Clearing brush can be very tiring, but having the right equipment can make it a lot easier. This guide will help you determine which type of brush cutter is right for you, and provide helpful tips and information for getting the most out of a cutter.

Brush Cutter Success Largely depends on four key things:

|

|

|

|

KEYS TO A HIGH-QUALITY BRUSH CUTTER

The cutter you purchase needs to have the required structural strength and quality components to withstand the stress that comes with this type of work. A heavy-duty, high-quality mower will eliminate extremely dense brush, cut small trees down to the ground in seconds, and last for many years.

Considerations Before You Purchase a New or Used Skid Steer brush cutter

Spindle Quality

![]() The spindle, also known as the bearing housing, is the most expensive and important performance part on a skid steer brush cutter attachment. Choosing a cutter with a thick, high-quality spindle is an absolute must when making a brush cutter purchase. Ask about the spindle material and diameter. Also, ask where the spindle was made to ensure you aren’t getting an inferior product. A forged spindle will be the strongest. A spindle shaft that has not been well maintained with proper lubrication will quickly wear out.

The spindle, also known as the bearing housing, is the most expensive and important performance part on a skid steer brush cutter attachment. Choosing a cutter with a thick, high-quality spindle is an absolute must when making a brush cutter purchase. Ask about the spindle material and diameter. Also, ask where the spindle was made to ensure you aren’t getting an inferior product. A forged spindle will be the strongest. A spindle shaft that has not been well maintained with proper lubrication will quickly wear out.

Replaceable Skid Shoes

Skid shoes add protection and increase the mower deck’s wear life. Skid shoes help the skid steer mower glide over soft, uneven terrain instead of gouging the ground.

Heavy-Duty Flywheel

A heavy-duty flywheel is needed for handling large debris. If it is too light, the brush cutter will bog down and hurt performance. A heavier flywheel will create more inertia and provide a cleaner, more precise cut. A circular flywheel will also bounce off stumps rather than catching and damaging expensive motor components. Remember, the spindle needs to be able to support the flywheel. Just because the flywheel is heavy does not mean it is good. The spindle needs to be able to take the jarring associated with cutting brush. They go hand in hand.

BRUSH CUTTER Blade DESIGN

There are two types of blades: updraft or flat. Updraft blades are like lawnmower blades; there is a bend in them to create lift for a cleaner cut in grass. Flat blades are better for cutting trees (like an ax) and are typically double sided for longer use. Blade thickness is of obvious importance, but an often overlooked detail is the length of the cutting surface. Oftentimes this is minimized to cut costs, which only makes cutting more inefficient.

Rocks, dirt, and other obstructions will dramatically increase the dulling of the blades. They will eventually need to be replaced, so ease of access and replacement cost are important to consider. Check the cost of replacement blade kits before buying and ask how to change the blades. Some do not have easy access and others weld the blade nut on, meaning a torch is required for replacement!

Mower Deck Reinforcement

Take a close look at the steel reinforcements on top of and under the mower deck — it has to be reinforced since it is the support structure for the entire mower. The deck should be constructed with thick, high-grade steel and cross members running across the entire length of the mower deck. When checking the deck’s bracing support, steel grade rating and steel thickness are all equally important. There should also be bracing around the motor to help withstand the tremendous force generated by the spinning flywheel and blades underneath the deck.

Reinforced Push Bar

The cutter will need a heavy-duty push bar to move trees out of the way. Without a push bar, the steel on the deck may quickly deform and affect the brush mower’s performance, or trees may topple back towards the skid steer.

Hydraulic Pressure Relief Valves

Pressure relief valves protect the motor and the loader’s hydraulic system from pressure spikes. When the blades hit a large stump or rock, the relief valves open and relieve pressure. This prevents seals or other internal components from damage due to excessive pressure.

POWDER COATING

Powder coating can drastically improve the longevity of your skid steer brush cutter. Before you invest, make sure that the brush cutter attachment has quality powder coating. With this simple step, you're more likely to get more life our your attachment, prevent fading, minimize rust, and resist scratches.

Safety Features

A skid steer brush cutter motor that features dynamic braking will safely stop the flywheel in about ten seconds. Without a braking system, the blades could keep spinning for minutes. Dynamic braking combined with pressure relief valves makes for a very reliable and low-maintenance drive system.

The brush cutter attachment should have a safety feature that prevents the cutter’s deck from going above the cab door. This keeps the cutter close to the ground and limits flying debris, which helps protect the operator.

Brush Cutter Deck Styles

There are two different style decks: open front deck and closed front deck (or standard deck). Whichever one is right for you depends on your cutting needs. We’ll start with closed deck cutters.

Closed Front Deck Brush Cutters

Applications

Applications

The deck style MUST be matched to the type and size of material cut. If you’re mainly clearing grass, weeds, undergrowth, and small trees and saplings up to 4” in diameter, then a closed deck cutter is a great choice.

Advantages

A closed front brush cutter does not allow debris to escape the deck easily, which allows extremely efficient mulching. Leaves, limbs, and saplings are shredded into small chips and pieces, resulting in a smooth and managed appearance. Closed front brush cutters provide a better-looking and more consistent cut than open front brush cutters. Some feature a floating deck which works well on uneven terrain.

Types and Options

The best cutter will depend upon the conditions in which it’s going to be used. Here are the basic types of closed front brush cutters and common options.

Fixed vs. Floating Closed Deck Brush Cutters

Fixed Deck

A brush cutter attachment with a fixed deck is designed for use on relatively level surfaces. If used on uneven terrain, the operator may have to constantly adjust the loader arms to prevent scalping. A fixed, standard deck brush cutter will be less expensive than a floating deck brush cutter.

Floating Deck

The floating deck is designed for use on slopes or uneven terrain. It produces a cleaner cut by following the contour of the ground to reduce scalping and gouging.

In situations where the floating deck is not needed, it has the ability to easily lock into a fixed position. For example, the operator may want to lock the deck in very soft or wet ground to keep the cutter suspended above the ground or if pushing over many trees.

Additional Options

Depending on your needs, additional features can be well worth a look. Some common options are front casters/wheels and rear rollers to help keep the skid steer mower stable.

Rear Roller

A roller consists of a large, tubular weldment with bearings connected to the outside of the deck. A Rear Roller will compact chopped material and produce a better cut by preventing the back of the deck from gouging into the ground.

A roller consists of a large, tubular weldment with bearings connected to the outside of the deck. A Rear Roller will compact chopped material and produce a better cut by preventing the back of the deck from gouging into the ground.

Swivel Casters/Wheels

Caster options provide support with pivoting solid steel wheels placed on both front corners of the brush mower. They help prevent the cutter from scalping and gouging, which results in a clean, consistent cut. 360° rotating swivel casters are better than fixed wheels because they make the brush cutter easier to maneuver from side-to-side.

Pairing Swivel Casters and a Rear Roller will help produce a better cut, a smoother ride, and further limit gouging/scalping. These options also provide extra value by minimizing wear on the underside of the brush cutter frame and skid shoes.

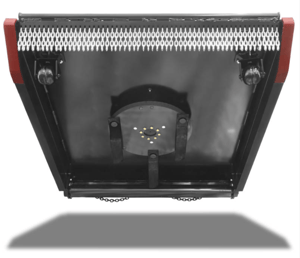

Open Front Deck Skid Steer Brush Cutters

Applications

Virnig open front cutters are designed to rough cut dense brush and trees up to 14” in diameter. These are better suited to tackle large areas of extremely tough brush with minimal impact on the property. If mainly cutting grass, an open front cutter is not the best choice, though it will work.

Advantages

An open front cutter is excellent for rough cutting trees and brush. It cuts debris without needing to push it over first. Brush exits the deck quickly, resulting in efficient cutting and less mulching. By tilting the front of the deck forward, small trees and stumps can be cut down to the ground to limit tree re-growth.

An open front cutter is excellent for rough cutting trees and brush. It cuts debris without needing to push it over first. Brush exits the deck quickly, resulting in efficient cutting and less mulching. By tilting the front of the deck forward, small trees and stumps can be cut down to the ground to limit tree re-growth.

Types and Options

There are less options when it comes to open front brush cutters. The basic determining factor is how large the material is to be cut and how often the cutter will be used. An open front cutter with a larger flywheel, spindle, and motor will cut larger material and more efficiently, but also costs significantly more.

OPEN Front vs. CLOSED Front brush cutters

Closed Front Cutters |

Open Front Cutters |

Application |

|

| Cuts up to 4” diameter trees, clears grass and brush continuously. | Cuts up to 14” diameter trees, clears grass and brush continously. |

How it Works |

|

| Pushes brush forward then shreds it. Debris does not escape the deck easily which allows most of it to be mulched. | Cuts trees without the need to push them over first. Brush exits the deck sooner, results in quicker cutting with less mulching. |

End Result |

|

| Provides a consistent, finished cut. | Provides a rougher, yet maintained cut. |

Options |

|

| Add Rear Roller and Swivel Casters to V50 Cutters to produce a better cut and prevent scalping. Pair these with the Floating Deck Cutter for ultimate versatility. | Add Carbide Teeth to the V60 Industrial Rotary Cutter to grind stumps and mulch material for a better end result. |

Matching a brush Cutter to Your Skid Steer

Effective mowing always requires a suitable machine. With so many options to choose from, it is important to match the brush cutter to the overall skid steer width, as well as the flow rate capabilities of your skid steer’s hydraulic system.

Cut Width

A common question is, “What width should I purchase?” You should purchase a brush mower with a cut width that is wider than the tires or tracks of your skid steer. If the cut width does not cover the tracks, then you increase the risk of running over uncut debris — debris that could damage your skid steer tires.

Bigger is not always better. Selecting a brush cutter attachment that is too wide will directly impact performance by:

- Increasing weight.

- Limiting maneuverability.

- Increasing overall cutting surface area, which ultimately means more power is required to run effectively.

Skid Steer Flow Rate

![]() You must know the flow rate of your skid steer and the minimum and maximum flow rate of the brush cutter motor. The flow rate is typically listed in gallons per minute (GPM).

You must know the flow rate of your skid steer and the minimum and maximum flow rate of the brush cutter motor. The flow rate is typically listed in gallons per minute (GPM).

To achieve optimal performance, the brush cutter’s flow rate should fall within the min/max range of the brush cutter motor. The motor is not designed to go over its maximum flow rate rating, and the warranty is likely void if it does. Picking a cutter with the correct motor will give a balance between blade tip speed and torque.

Flow rate examples:

- If you use a Standard Flow brush mower motor in High Flow, the motor will be over stressed. It may not fail immediately, but irreparable damage has likely occurred and eventually the motor will fail.

- If you use a High Flow brush mower on a Standard Flow skid steer, you won’t get adequate performance.

Skid Steer Operating Capacity

Always check the attachment’s recommended loader capacity to make sure your skid steer has the necessary operating capacity to effectively handle the skid steer brush mower.

Safely Operating and Maintaining Brush Cutters

![]() For maximum safety, take the time to read and understand the brush cutter’s manual before operating. The key things are to keep bystanders at least 300 feet away from the cutter when it is being operated and have a shatterproof cab door on your skid steer.

For maximum safety, take the time to read and understand the brush cutter’s manual before operating. The key things are to keep bystanders at least 300 feet away from the cutter when it is being operated and have a shatterproof cab door on your skid steer.

Terrain changes can come up quickly. If you are unfamiliar with the terrain, be sure to walk around and see if there are any sudden drop-offs or soft, mushy areas. Also, look for rocks, wire, and other damaging debris before cutting.

Skid steers and brush cutters are very heavy. On dry ground weight is not a concern, but cutting on wet ground will likely cause the skid steer to lose traction and sink deep into the ground. This problem cannot be completely avoided, but traction can be increased by using a machine with tracks instead of tires. Also, work from dry areas into wet areas by facing the wet area. This way if the machine starts sinking you can still back up. If you’re working parallel along a wet area and the machine starts to sink, backing out likely isn’t going to be an option.

brush cutter Maintenance

Whether you buy a new or used skid steer mower, it is always important to keep up with regularly scheduled maintenance and replace worn or defective parts as soon as they are detected.

The most important maintenance tip we can give you is to keep the spindle well lubricated at all times. We receive many cases of part failure that could have easily been prevented with proper lubrication.

Also, keep a close eye on wear parts like the blades and skid shoes. The brush mower will have areas that must be greased, and the motor oil needs to be checked regularly and filled with the proper oil. Use the cutter’s manual for maintenance information and stick to a schedule. You can count on years of reliable performance if it is well maintained.

Here are some general tips to safely operate skid steer brush cutter attachments.

- When operating, never lift the blades above the cab door.

- Never operate a brush cutter without a shatterproof cab door on your skid steer.

- Before cutting, look for rocks, fence wire, or other damaging items.

- It is important to never exit the skid steer when the cutter’s blades are in motion. Anytime the blades are off the ground or still moving they can be very dangerous.

- Since debris can easily be thrown through the air, make sure there are no bystanders within 300 feet.

- Make sure the front of the deck isn’t plowing/gouging into the ground.

Virnig Brush Cutters

When it comes to skid steer brush cutters, it doesn’t get better than Virnig. Every cutter is designed and manufactured in Rice, Minnesota. With over 60 models to choose from, there’s a cutter for any brush clearing application.

When it comes to skid steer brush cutters, it doesn’t get better than Virnig. Every cutter is designed and manufactured in Rice, Minnesota. With over 60 models to choose from, there’s a cutter for any brush clearing application.

Each cutter features a reinforced deck, premium motor and spindle, and a heavy-duty flywheel/blade combination. The unmatched design and durability along with a proactive customer support team means long-lasting performance.

Virnig Manufacturing offers nine different cutters:

Click on any product name to view its specs in full.

Virnig's Naming Series

For attachments with comparable counterparts, there are a variety of factors to determine the series. This includes steel thickness, amount of bracing, capacity, or simply the number of options to specialize the attachment.

|

Mini skid steer attachments designed for peak performance and crafted to be the toughest in the market. Small but powerful, they embody Virnig quality. |

|

Ideal for compact tractors and small skid steers with less than a 1,500 lb operating capacity. |

|

Lighter-duty with minimal options for small to medium frame skid steers. Works well for homeowners and DIYers. |

|

For medium to large frame skid steers. Though this is Virnig’s standard-duty line, the V50 Series often outperforms other brands’ heaviest skid steer attachments. |

|

High-Performance attachments constructed for large frame skid steers. Ideal for commercial operations, they are designed to withstand years of tough jobs. |

|

Virnig’s new attachment class with the best durability and performance; solely contains the Tree Disc Mulcher. As skid steers increase in size and jobs become more demanding, Virnig will continue to add to the V70 line-up. |

About Virnig

Located in the heart of Central Minnesota, Virnig Manufacturing has been designing and producing skid steer attachments since 1989. From engineering and cutting raw materials to machining, welding, and powder coat painting the finished product, all steps of the manufacturing process are done in-house.

Our skid steer attachments’ major components are manufactured with the latest technologies to yield a product that continually outperforms the competition. The product line is backed by a 1-year warranty and an on-going customer support system. Plus, Virnig carries over 40,000 attachment parts that are in stock and ready to ship the same day an order is received.