When looking for a skid steer bucket attachment, there are many things to consider besides price. Buckets are built for many different jobs and applications, and finding the right one for you will depend on a few factors. Use this guide to find a quality skid steer bucket that best fits your needs, while getting the most out of your investment.

Bucket Success Largely Depends on Five Key Things:

Determining Specific Bucket Needs

Buckets tend to fall into five categories:

- Dirt

- Utility

- Snow/Light

- Multi-Purpose

- Specialty

Each type has several different applications it’s best suited for and contains a few pros and cons depending on the job.

Starting with an understanding of what you'll be using a bucket for will help you make the best, most cost effective choice.Begin the selection process by evaluating your application for the bucket. Will you be using it mostly for loading, spreading, digging, handling loose material—or maybe a combination of these jobs? Learn the characteristics of each job to ensure you’re getting the right fit.

Talking to a dealer can help. If you explain your requirements to one of those pros, they should be able to provide you with a good recommendation.

Identifying a High-Quality Bucket

A well-built, heavy-duty bucket will last for many years and be cost-effective. But when almost every skid steer attachment manufacturer says they have high-quality, dependable buckets, how do you know which ones actually deliver? The best buckets will have intelligent design, structural strength, and proper reinforcement to withstand the stress that comes with this line of work.

Here’s what to look for.

Design/Reinforcement

- Certain design elements will indicate longevity. Look for reinforcement plates, which increase a bucket’s durability. For example, bracing along the outside and inside of a bucket are clear indicators it was built to last.

- Check if there are wear bars on the bottom of the bucket. Wear bars extend the life of the attachment by helping prevent the bucket bottom from completely wearing through.

- If the bucket has tines, then a cross member is often essential. A cross member is a piece of metal that spans across the bottom tines of a skeleton bucket to increase overall strength.

Construction

Since buckets are made of steel, steel quality is a very important factor in the decision process. High-strength steel resists wear and increases the lifespan of a bucket. The steel’s thickness and grade (yield strength) are what comprise the foundation of a quality bucket.

Yield strength is the amount of stress a material can withstand before permanently deforming, which makes it an important factor when comparing buckets.

A higher yield strength means a stronger, better bucket. While using higher grades of steel does increase the upfront cost of an attachment, it saves time and money over the lifetime of the attachment. Think of it as an upfront investment to protect your productivity and bottom line.

For example, a bucket made from 1⁄2” Grade 50 steel plate (50,000 PSI minimum yield strength) will be nearly 30 percent stronger than one made with A36 (36,000 PSI minimum yield strength). And a stronger bucket will hold up against higher stress.

Always look through the specs to find the overall weight. A heavier bucket usually means heavier-duty. Virnig buckets weigh upwards of 800 lbs while other manufacturer’s buckets are often hundreds less. Where does the extra weight come from? It comes from thicker steel throughout the bucket along with additional reinforcement and bracing.

Bucket Types/Options Available

Low Profile Dirt Bucket

- For most applications, a traditional dirt bucket is likely the best choice. Dirt buckets generally are solid choices for digging, grading, and transporting material. The material’s density and ground conditions will dictate whether you need to upgrade to a heavy-duty dirt bucket. Constructed from a greater thickness and higher grade of steel, heavy-duty buckets are designed with added durability for harsh applications.

- Visibility is very important when doing dirt work. If you can’t see the bucket edge, it’ll be more difficult to properly grade. Dirt buckets have a low-profile design with lower sides and back and an extended bottom which allows the operator to see the bucket’s edge.

- Achieving a smooth grade is often more difficult than it seems. Buckets with a grading bend allow better grading than what you’ll see with a standard bucket. Additionally, the grading bend comes with a rolled inside for easier material cleanout.

HIGH CAPACITY Dirt Bucket

- It has all the benefits of a low profile dirt bucket but is designed stronger, deeper and taller to haul more material. The bottom is extended for better visibility of the cutting edge. It features an additional bar across the entire bottom rear of bucket for increases strength and bucket heel wear. These are made for everyday use on medium to large frame skid steers and it’s the strongest skid steer dirt bucket that Virnig builds.

DIRT BUCKET SIDE CUTTERS

- Side cutters improve penetration in hard, compact soils. They also increase cutting width and bucket side protection. Virnig Side Cutters are reversible—the only ones in the industry designed this way.

Utility Bucket (General Purpose)

Utility buckets are a jack of all trades type-attachment. Like the dirt bucket, they can be used in nearly any industry application effectively. The taller design allows more volume than a dirt bucket, yet they’re built heavier than a snow/light material bucket. But, there is no option for a grading bend or side cutter available.

Snow/Light-Material Bucket

Snow/light material buckets are deep with a high back and sides to carry larger volumes of lighter/loose material, such as snow, mulch, wood chips, sawdust, bark, etc. If moving light material, you may want to consider a bucket with a higher struck capacity to move more material in less time.

These buckets aren’t intended for digging. While they have more capacity than a dirt bucket, they're often lighter and don’t have the same strength. It’s best to leave the dirt work to the other buckets by respecting the nature of its intended use.

Multi-Purpose (4-in-1) Bucket

Multi-purpose or 4-in-1 buckets can perform multiple functions because the bottom and sides can separate from the back. This combination bucket enables operators to dig, load, carry, and dump material like a standard bucket. Plus it can grip debris like a grapple, grade dirt, and level dirt.

When closed, a 4-in-1 operates like a standard bucket, and it has the added advantage of being able to dump at maximum height. You can simply open up the bottom of the bucket and spill out the material.

When open, the back of the bucket can serve as a dozer. Because of its clam-style design, a 4-in-1 bucket can also operate like a grapple and pick up materials that can’t be handled with a standard bucket.

Although multi-purpose buckets offer distinct advantages, there are some drawbacks to consider. The added weight of the cutting edges and hydraulics reduce the overall material weight the bucket can carry. For example, a Virnig 72-in. V60 Dirt Bucket weighs 700 lbs., whereas its 72-in. V50 4-in-1 Bucket weighs 960 lbs. It’s important to consider whether or not the added weight will leave your skid loader with enough lift capacity to do its job.

In addition, the extra capabilities of 4-in-1 buckets does increase cost. You can expect to pay up to three times as much, or more, compared to similar-sized dirt buckets. Because of this, you’ll want to evaluate how valuable these extra features are to you.

Specialty Buckets

Skeleton Rock Bucket

Rock buckets are incredibly strong and effective for removing rock from the ground. They’re made almost entirely of steel tines set 3” or 4” from each other. When lifting objects, large debris and rocks stay inside the bucket, while the soil is sifted out the bottom in the spaces between the tines.

Tine spacing on skeleton rock buckets impacts how well material is sorted. Ideally, the unwanted material (usually dirt) should easily pass through the tines.

The increased visibility provided by the open, skeletal back ensures fence posts or other damaging debris won’t easily go unnoticed and puncture one of your tires. Also, the shortened height allows the cutting edge to remain visible to the operator.

Additional uses include digging roots from thick brush, clearing overgrown fence lines, removing brick or cement chunks around building projects, and efficient back-dragging. Whether it’s for landscaping, construction, or farming the rock bucket is absolutely essential to scoop up unwanted, solid material.

High Dump Bucket (Roll-Out Bucket)

High dump buckets extend reach and increase dump height. They provide maximum cutting edge to ground clearance during dumping, and operators can rotate this bucket into a full, 90-degree dump.

High dump buckets are ideal for loading feed mixers and dump trucks. In the fall, they can be used for harvesting potatoes, and in the winter they can be used for moving snow. They're also useful for recycling and garbage removal applications.

Increase the overall life of the cutting edge by adding an optional bolt-on edge or serrated edge (SEE BUCKET EDGE OPTIONS SECTION).

Concrete Bucket

The concrete bucket is designed to carry and pour concrete and other free-flowing materials like sand, dirt, stone, and feed. This allows for quickly pouring sidewalks, driveways, footings, and other areas. Great for times when you can’t get a truck in the place/position you want, or when a dump truck would be overkill. It can benefit your crew, too; often eliminating the use of a wheelbarrow and reducing manual labor.

There are two sizes available: A 1/2 yard version for smaller machines and a 3/4 yard version for larger machines.

Stump Bucket

This skid steer attachment is a specialized digging tool designed for maximum leverage when forced underneath large boulders, stumps, and structures. It takes a conventional bucket to an entirely different level. Stump bucket teeth cut into rocky soil, scoop loose dirt, and dig out roots. Some operators use this bucket for digging trenches or removing Prickly Pear Cactus.

Look for stump buckets with replaceable teeth since welded ones will be difficult to remove when it’s time for replacement.

Manure Slurry Bucket

It’s a dirty job, handling and transporting manure. Not only can it present a challenge, this particular bucket offers the solution. The bucket features a top-formed profile to limit spillage and a rolled-inside profile for easier manure clean out. The 60-degree back angle better holds slurry material inside the bucket. If you operate in a colder climate, you might want to consider adding a bolt-on or serrated edge to help scrape frozen manure.

A manure slurry bucket can help keep animal feeding areas clean.

Bucket Edge Options

Most buckets come with a weld-on cutting edge. There are four other edge options available: bolt-on, toothbar, weld-on teeth, and serrated. Having the right edge option can boost job productivity and eliminate the need to buy another bucket. While there’s not a one-size-fits-all answer to which is better, knowing the advantages of each will give you a better idea of which edge will work best for your operation.

Options

Bolt-On Edge

This is the most common cutting edge. Bolt-on edges protect and add strength to the front end of the bucket. They’re replaceable and can be reversed before the edge wears back into the bucket. Once both sides wear completely, the edge can easily be replaced.

Quick Tip

Don’t try to reuse the bolts when reversing the bolt-on edge, as the threads get damaged in use and the bolts won’t be reusable. Instead, just cut them off with a torch and replace.

Serrated Edge

Another option to consider is the serrated edge. These are bolted on the bottom lip of a bucket and are easy to remove or replace—like a toothbar. They’re designed to loosen hard-to-penetrate materials like packed gravel. These bucket edges excel in breaking up frozen ground.

There’s some unmatched strength involved with this type. With a serrated edge, you’ll never have to worry about breaking a tooth or shank. They’re strong like a standard bolt-on edge because when the edge contacts the ground the force is exerted across the entire edge. Also, the serrated edge limits the bucket lip from wearing out, which minimizes repair costs and time spent in the shop.

Quick Tip

If you primarily need to smooth out or scrape roadways, the serrated edge is a great option to help cut through tough compact gravel or ice—you can always remove it later if necessary.

BOLT-ON BUCKET TEETH (TOOTHBAR)

Adding a toothbar to a skid steer bucket will drastically increase its digging ability. It’ll help cut into rocky soil, scoop loose dirt, and dig out roots. It’s a powerful style designed to be relentless.

Despite its relentlessness, the toothbar is both removable and easy to repair or replace. Since the whole edge is removable, the bucket is more versatile, the only downside is cost. Toothbars are more expensive than the weld-on teeth but customers who benefit from the toothbar’s versatility find it is well worth it.

For example, operators usually don’t want a toothbar (or teeth on the bucket) when clearing snow or back dragging. But, they do want the teeth when they’re digging out roots. Having the ability to remove the toothbar gives you the versatility to use the bucket either way. A weld-on doesn’t give you that option. If you don’t see yourself ever wanting to remove the toothbar, then weld-on teeth are probably the wiser choice.

Take note: weld-on teeth can’t be paired with a standard bolt-on edge, but a toothbar can.

Quick Tip

Don’t use a tooth bucket with missing teeth. This will wear out the shank and the tooth won’t fit properly when replaced. It’s best to keep extra teeth on-hand and replace them as needed. Regularly inspecting these teeth is recommended.

Weld-On Teeth

Like toothbars, weld-on teeth excel at breaking up compacted soil, catching rocks, and removing roots, but these are permanent and can’t be removed. Since the teeth are welded directly to the bucket, they’re stronger than a toothbar. The added strength helps it perform better in tough, seemingly impenetrable soil conditions (like clay).

If you will be back dragging, grading, or plowing snow, then weld-on teeth may present a problem. Many operators don’t realize the drawback of non-removable teeth until they’re well into a project and the lack of versatility suddenly causes a big headache.

Quick Tip

Don’t choose weld-on teeth simply because they’re cheaper than a toothbar. By choosing weld-on you’ll save some money but realize versatility will be sacrificed.

Matching a Bucket to Your Skid Steer

Properly matching a bucket to your machine is critical for optimal performance. Selecting the wrong one can increase costs and accelerate wear.

Below are four important questions and a calculation you should consider before purchasing a bucket.

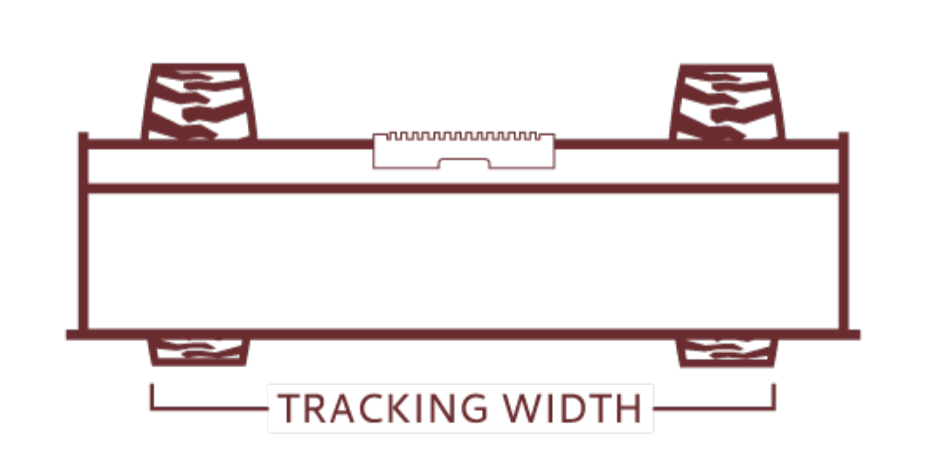

What Width Should I Purchase?

The first step is to figure out what width you need. We recommend choosing a bucket that’s wider than the tracking width of your skid steer. Choose a bucket too small and you’ll have to make more trips, which results in higher operating costs and increased timelines.

Keep in mind, bigger isn’t always better. The bucket should be big enough for what you need to do, but not too big that the machine can’t effectively lift and haul material without being overloaded or tipping forward. That scenario presents a different type of headache.

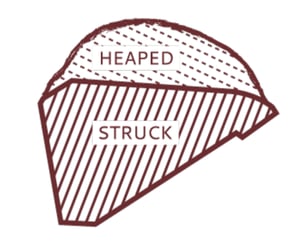

Bucket Capacity: Struck vs. Heaped

There are two types: struck capacity and heaped capacity. These are measured in cubic feet (ft3).

- Struck is the volume of material held in a bucket when a straight edge is slid across the top and bottom edge of a bucket; it does not include any material outside the bucket.

- Heaped is the volume of material held inside a bucket plus the amount piled on top of it. Heaped capacity is typically 20% more than struck capacity. Use heaped capacity in the calculation below if you want to stay on the safe side.

Knowing the bucket capacity will help you determine the total weight of the material in the bucket, or payload.

You need to ask yourself, “what material do I plan on lifting and moving most often?” Find the density of that specific material and use it in the calculation below.

For example, dry/loose dirt has a material density of 80 pounds per cubic foot (lbs/ft3).

Why Is Operating Capacity Important?

To simply answer that question—safety and efficiency.

To determine operating capacity, each model of skid steer is tested using the same procedure.

The loader is parked on a flat surface, and a bucket is raised to a point where it’s furthest from the operator. With the bucket extended, it’s filled with weights until the rear wheels of the skid steer lift off the ground, in other words, until it tips slightly forward. That measurement is the tipping capacity or tipping load.

- A skid steer with a 3,000-lb tipping capacity may not be able to lift a 3,000-lb object off the ground. Therefore, operating capacity comes into play. Operating capacity is no more than 50% of tipping capacity. It’s the total weight the skid steer can safely lift, and is a safety margin set by the manufacturer.

- For example, a skid steer with a 4,000-lb tipping capacity will likely have an operating capacity of 2,000 lbs, which means it can safely lift 2,000 pounds or less. You wouldn’t want to be lifting something that weighs over 2,000 lbs. Depending on the skid steer, the capacity can range anywhere from 800 to over 4,000 lbs.

If you don’t know your machine’s operating capacity you may FIND IT HERE.

If you don’t know your machine’s operating capacity you may FIND IT HERE.

Lifting is often the most demanding work a skid steer will perform in its lifetime. Some buckets will be too big or too small for your skid steer, so it’s important to match it to your machine to ensure it isn’t underutilized or overloaded.

In order to do this, you need to find the total load weight, which is the bucket weight plus weight of the payload. Then make sure it doesn’t exceed your skid steer’s operating capacity.

What's The Calculation?

Use this equation to quickly estimate if the bucket you choose, along with the material you’ll be hauling, will or won’t overload your skid steer. Remember to use heaped bucket capacity if you want to stay on the safe side.

Bucket Capacity (ft3) x Material Density (lbs/ft3) + Bucket Weight, w/ Edge (lbs) = Total Load Weight (lbs)

Total Load Weight (lbs) - Skid Steer Operating Capacity (lbs) = Result (lbs)

If the result is a negative number, the skid steer is overloaded. In this case you should choose a lighter bucket. A positive number indicates the skid steer isn’t overloaded.

We also have a skid steer bucket load calculator you may find useful here.

Safely Operating and Maintaining Buckets

Problems and sudden expenses are always frustrating no matter your line of business, but take solace in the fact that many are avoidable.

With good technique, a few industry tips, and some preventative steps, avoiding future bucket issues will become easier and your bucket can have a longer lifespan. On the other hand, neglecting safe operation and maintenance can diminish a bucket’s lifespan and put your crew at needless risk.

Buckets are simple and inspections are critical to the ongoing upkeep and maintenance of the attachment. Periodically check for cracks, stress fractures, and excessive wear. The quick-tach plate is a commonly damaged part on a bucket. If cracked or extremely loose, don’t use it, plain and simple. It always requires a solid fit. If not fitting correctly, it requires cleaning, repair work, or perhaps a new plate or bucket. Always make sure the bucket is properly mounted to the skid steer before operating.

Don’t let mud or other debris build up in the quick-tach connection area. Check for debris in the quick-tach area before each hook-up. Keeping this area clean will make it safer and easier when connecting to attachments.

Grading is all about technique. Pressure is probably the most important factor when grading. Too much pressure and you’ll find it hard to grade with any kind of finesse, also it’ll cause unnecessary wear to the bottom of the bucket. Speed is also a factor.

Refer to Virnig’s FINISH GRADING GUIDE for more operational tips.

Quick SAFETY Tip:

Never attempt to lift (attachment weight + payload) more than the operating capacity of your skid steer.

For attachments with comparable counterparts, there are a variety of factors to determine the series. This includes steel thickness, amount of bracing, capacity, or simply the number of options to specialize the attachment.

|

Mini skid steer attachments designed for peak performance and crafted to be the toughest in the market. Small but powerful, they embody Virnig quality. |

|

Ideal for compact tractors and small skid steers with less than a 1,500 lb operating capacity. |

|

Lighter-duty with minimal options for small to medium frame skid steers. Works well for homeowners and DIYers. |

|

For medium to large frame skid steers. Though this is Virnig’s standard-duty line, the V50 Series often outperforms other brands’ heaviest skid steer attachments. |

|

High-Performance attachments constructed for large frame skid steers. Ideal for commercial operations, they are designed to withstand years of tough jobs. |

|

Virnig’s new attachment class with the best durability and performance; solely contains the Tree Disc Mulcher. As skid steers increase in size and jobs become more demanding, Virnig will continue to add to the V70 line-up. |

Virnig Bucket Attachments

- V20 HIGH CAPACITY DIRT BUCKET

- V60 HIGH CAPACITY DIRT BUCKET

- V50 MULTI-PURPOSE BUCKET (4-IN-1)

- V60 MULTI-PURPOSE BUCKET (4-IN-1)

- V20 SNOW / LIGHT MATERIAL BUCKET

- V40 SNOW / LIGHT MATERIAL BUCKET

- V50 SNOW / LIGHT MATERIAL BUCKET

- V60 SNOW / LIGHT MATERIAL BUCKET

- V20 LOW PROFILE DIRT BUCKET

- V40 LOW PROFILE DIRT BUCKET

- V50 LOW PROFILE DIRT BUCKET

- V60 LOW PROFILE DIRT BUCKET

- V20 SKELETON ROCK BUCKET

- V30 SKELETON ROCK BUCKET

- V30 SKELETON ROCK BUCKET

- V40 SKELETON ROCK BUCKET

- V50 SKELETON ROCK BUCKET

- V60 SKELETON ROCK BUCKET

- V50 UTILITY BUCKET

- V60 UTILITY BUCKET

- HIGH DUMP BUCKET

- CONCRETE BUCKET

- STUMP BUCKET

- MANURE SLURRY BUCKET

If you’d like to learn more, you can request a quote or find a dealer near you.

Located in the heart of Central Minnesota, Virnig Manufacturing has been designing and producing attachments since 1989. From engineering and cutting raw materials to machining, welding, and painting the finished product, all steps of the manufacturing process are done in-house by experts.

The skid steer attachments’ major components are made and manufactured with the latest technologies to yield a product that continually outperforms the competition.

The product line is backed by a 1-year warranty and an ongoing customer support system. Plus, Virnig carries over 40,000 attachment parts that are in stock and ready to ship the same day an order is received.